Broken Decapping Pins, Stuck Primers, and Press Jams: How to Fix the Most Common Decapping Problems

Why Decapping Is the Most Overlooked Step in Reloading (and Why It Causes So Many Problems)

Most reloaders don’t think much about decapping until something goes wrong:

Broken pins.

Press jams.

Bent shafts.

Primer ringers.

And many of these issues are due to:

Improper threading on decapping pins.

Military crimped primers.

Incorrect decapping pin size.

Small flash holes.

Flash holes off center.

Decapping is the very first operation in your reloading workflow and when it’s inconsistent, every step after it suffers. If you’re fighting your press at the decapping stage, it can sometimes be your technique, but typically problems arise as the result of the brass you’re reloading and the reloading dies you’re using.

Let’s break down the most common decapping problems reloaders complain about and how to fix them for good.

The 4 Most Common Decapping Problems and Why They Happen

1. Broken Decapping Pins

Broken decapping pins can happen for a number of reasons. First and of utmost importance, the decapping pin must be installed properly in the decapping shaft to prevent backing out of the threads. If the decapping pin loosens, then it is more likely to break. An easy fix for this and what we highly recommend is adding a touch of Loctite between the tip of the shaft and the shoulder of the decapping pin, where the two meet. This simple, yet critical step can solve many of your decapping issues.

Second, decapping pins can break as a result of decapping military brass and heavily crimped primers, which are notorious for snapping pins. Cheap pins flex, work-harden due to the metal stiffening, and eventually fail. It is important to use a decapping die precision machined from high quality materials, in particular a hardened steel shaft and pin.

Third, we also encounter brass that either has a small flash hole, for example in Lapua or Norma brass, with a .062 diameter flash hole (while standard flash hole size is .081 diameter) or brass with a flash hole off center. It is important you inspect the brass you’re reloading with first, before deciding if the brass is able to be decapped or reloaded. In cases with an off-center flash hole this will undoubtedly cause decapping issues. In cases with small flash holes, it is important to deprime using the proper pin size, for example Mighty Armory offers .058 diameter decapping pin size to easily accomplish this decapping job.

Why Decapping Pins Break if Unrelated to the Brass:

- Soft steel pins

- Poor alignment

- No shock absorption in the die

How to fix it:

Use hardened tool steel pins with proper alignment and a die body that doesn’t allow the case to cant or wobble during decapping.

2. Primer Pullback (Primers Getting Stuck in the Case)

This one is infuriating. You decap, and the primer doesn’t fall free, it rides back up into the pocket.

Why primers pull back:

- Primer sticks to the pin

- No positive ejection system

- Weak or inconsistent flick action

How to fix it:

A spring-loaded primer flicker system snaps the primer cleanly off the pin, preventing pullback and reducing chute jams on presses.

Mighty Armory offers multiple spring-loaded primer flicker options in their decapping dies to prevent primer ringers and primer pull backs.

For example, if you’re decapping on a single stage or turret press, the Mighty Armory PUA and Magnum Decapping Dies utilize a spring-loaded primer flicker. The cap and spring design allows upward shaft movement before contacting a stop. The rebound of the spring forces the shaft down and flicks the primer off the pin, shooting it through the press funnel.

If you’re decapping on a progressive or autodrive press, the XMS steel decapping die is 100% the right choice for you. This die utilizes a double spring action to not only flick your primer out of the pocket but also dynamically centers your brass at speed.

3. Press Jams on Progressive and Autodrive Presses

Progressive and autodrive presses are amazing until a primer hangs up and stops everything. These presses magnify every small problem in your decapping setup. What feels like a minor hiccup on a single-stage press becomes a full-on workflow killer when you’re running volume on a Dillon 650/750/1100, Mark 7 or similar.

One of the biggest issues we find is case wobble in the shell plate when decapping at speed. The autodrives in particular, allow more lateral movement than single stage and turret presses. If the decapping die doesn’t guide the case into perfect vertical alignment, the case can cant slightly and cause bent pins, the pin can miss the flash hole and will create jams and issues.

Why jams happen:

- Primers not ejecting cleanly or hang up in the chute

- Primer pullbacks

- Cases wobbling in the shell plate

- Decapping pin deflecting under load

How to fix it:

Look for a decapping die with:

- Auto-centering case guidance

- Spring-loaded primer ejection

- Tight vertical alignment

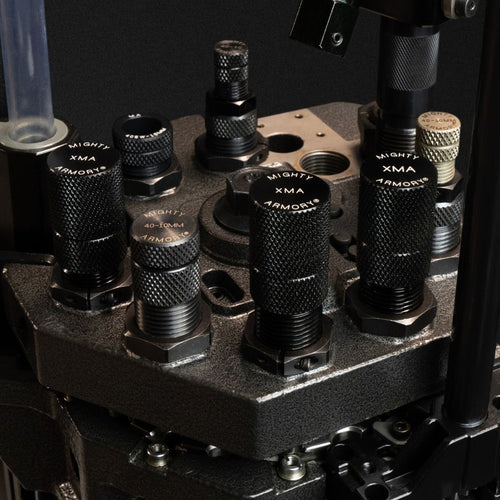

This reduces stoppages and keeps your press running smoothly. The Mighty Armory XMS Steel Decapping Die is reloaders choice for getting the decapping job done. Complete with dual spring action, hardened steel body, shaft and decapping pin, and an autocentering case guide to ensure your cases are in perfect vertical alignment in the shell plate will prevent many of the irritating issues that reloaders face during the decapping process.

4. Bent Shafts & Wobble at Speed

If your case isn’t perfectly centered, your pin takes side loads. Over time, that leads to bent shafts and inconsistent decapping. The autocentering function of the Mighty Armory XMS Decapping Die will solve this problem.

In addition, it is imperative that you add a touch of Loctite between the shoulder of the decapping pin where it meets the shaft. This will prevent many of your bent shafts and broken pin issues.

Why it happens:

- No case guide

- Loose tolerances in the die body

- Weak shafts

How to fix it:

An auto-centering case guide keeps the case vertical and aligned with the pin especially important for high-volume progressive runs. In addition choose a decapping die that uses quality steel and heat treated and tempered shaft and pins for added strength.

What Reloaders Look for in a Quality Decapping Die

If you reload at volume especially on Dillon, Mark 7 or similar progressive presses or autodrive presses your decapping die should have:

- Hardened tool steel construction

- Spring-loaded primer flicker

- Auto-centering case guide

- Replaceable decapping pins

- Tight vertical alignment

- Built to SAAMI case geometry

- Durability to handle crimped primers

If your die doesn’t check these boxes, you’ll eventually fight broken pins, stuck primers, and unnecessary downtime.

Why the XMS Decapping Die Solves These Problems

The Mighty Armory XMS Decapping Die with Case Guide - Built for High Volume Reloaders was built specifically to eliminate the most common failure points reloaders complain about:

- Spring-loaded primer flicker snaps primers free

- Auto-centering case guide keeps cases vertical at speed

- Hardened tool steel pin & shaft handles crimped primers

- CNC machined body maintains perfect alignment

- Designed for progressive & autodrive presses

It’s the difference between “getting through decapping” and running your press smoothly, consistently, and without stoppages.

The XMS Decapping Die includes two decapping pins - one .058 diameter and one .078 diameter to accommodate the wide range of brass available. The pins are swiss-machined with rolled threads and heat-treated for ultimate strength. The .078 diameter pin has a bend rate of over 1,000 pounds. Mighty Armory is highly known for having the best decapping pins in the reloading market trusted by competitive shooters and volume reloaders world-wide. Be sure to put a touch of thread locker between the decapping shaft and pin before use.

Pro Tip: Decapping Is the First Step of Precision Reloading

Reloaders obsess over sizing dies, seating dies, and crimp consistency but none of that matters if your brass prep is inconsistent.

Clean primer removal =

✔ cleaner primer pockets

✔ better primer seating

✔ more consistent ignition

✔ smoother progressive operation

Precision doesn’t start at sizing. It starts at decapping.

Final Takeaway

If you’re snapping pins, fighting press jams, or dealing with primers getting pulled back into cases, your decapping die is the bottleneck in your process.

Fix that first and the rest of your reloading workflow instantly gets smoother, faster, and more consistent.

Recommended Setup

- XMS Decapping Die

- Replacement Hardened Steel Decapping Pins

- XMA Hold Down Tip (for swaging setups) because BONUS. The die is easily converted for a hold down setup by simply swapping the pin