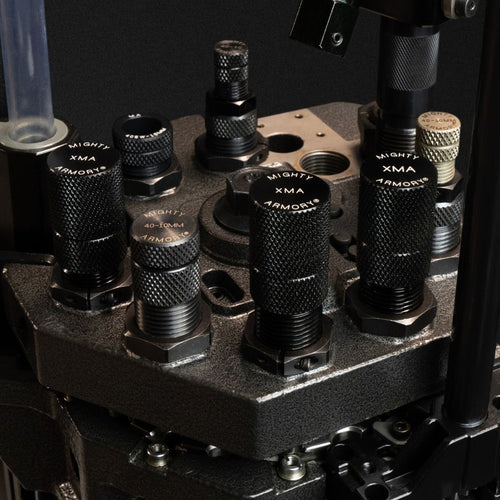

A GUIDE TO RELOADING 9MM TO SAAMI SPEC WITH MIGHTY ARMORY RELOADING DIES

A GUIDE TO RELOADING 9MM TO SAAMI SPEC WITH MIGHTY ARMORY RELOADING DIES

Contents

- Introduction to loading 9mm ammo with Mighty Armory SAAMI Spec Dies

- Decapping 9mm with Mighty Armory Dies

- How to size a 9mm case with Mighty Armory Full Length Die

- How to Flare & Expand a 9mm case with Mighty Armory Flare Die

- How to Seat a 9mm case with Mighty Armory Seating Die

- How to Crimp a 9mm case with Mighty Armory Taper Crimp Die

- Reloading 9mm with Mighty Armory's Measured System with different bullet diameters

- Conclusion

Introduction

If you’ve ever thought about reloading your own 9mm ammunition, Mighty Armory will make it easy and accurate for you to achieve maximum performance.

In this post, we’re diving into how to set up Mighty Armory’s full-length carbide 9mm reloading dies using four different .124 grain bullets, each with different widths and different diameters – RMR .355, Acura Outdoors .356 plated, Hoosier .356 coated and Armscor .354 jacketed bullets. When using the Mighty Armory reloading dies with their measured system, no matter which bullets you choose, it will become extremely easy for you to achieve SAAMI Spec diameters resulting in precision and reliability in your reloads.

Mighty Armory’s SAAMI Spec 9mm Sizing Die sizes the case to full length, which is different from what we reloaders have come to know about under-sizing. However, full length sizing produces a much more accurate round with additional benefits including eliminating case bulge, better chambering, greater accuracy, longer brass life, cleaner round burn and more.

The Mighty Armory carbide dies are precision engineered to provide full-length sizing, similar to what you'd find with rifle dies. This means you get more consistent rounds and better overall performance.

Using Mighty Armory’s measured system will work seamlessly with various reloading presses, whether you’re using a turret press, a single-stage press, or an automated system, setting up the 9mm dies is easy to accomplish.

Decapping with Mighty Armory Dies

The Mighty Armory Sizing Die comes with a primer-flicker spring decapping system that is built into the cap. The spring design allows upward shaft movement before contacting a stop and the rebound of the spring forces the shaft down, which flicks the primer off the case. If you've ever experienced primer pullback or primer ringers, this is your solution.

Note: Using the decapping feature with the sizing die is optional. Some reloaders prefer to decap before sizing. If you choose to decap with the Mighty Armory Sizing Die (or any other Mighty Armory Decapping Die) be sure to add a touch of Loctite or Virba-tite on the decapping pin threads and let set for 15 minutes. This will prevent the pin from backing out and prevent possibility of pin breakage.

Now onto the die setup…

Step 1: Mighty Armory Full Length Carbide Sizing Die Set Up

The first thing you want to do is turn the Mighty Armory 9mm Carbide Sizing Die all the way down into your tool head. This applies whether you're using a turret press, Dillon, Hornady Lock-N-Load, Mark 7, Frankford Arsenal or any other press. Turn the die down until it touches the shell plate or shell holder (with ram all the way up) without applying pressure. Then tighten the lockring to secure the die in place.

Next, grab a polished 9mm case. Mighty Armory recommends using a wet tumbler for cleaning. Fill the tumbler about three-quarters full with brass, add hot water, and about a half tablespoon of dish soap (Dawn de-greaser is preferred). Add stainless steel media to deburr the case mouths and rims. Stainless steel media will eliminate the possibility of filing from stacking up in your die, which can cause scratches on the case. Now let the hot water and tumbling do the work. This method usually takes about 1-2 hours to clean a thousand cases. Some of the brass might have a bulged head, commonly known as glock bulge. Don’t worry; the Mighty Armory full length sizing die can handle that. If you see a shiny spot on the case after sizing that is likely the result of the sizing die removing the case bulge.

If the case has major head bulge you do need to roll size as any die will cause a ledge of brass around the bottom of the case.

As you size the case, you’ll notice it comes out shiny and smooth. You can tumble the brass in corn from here to give it shine.

Step 2: Mighty Armory Flare Expander Die Setup

Flaring the case is the most critical step during reloading. The Mighty Armory 9mm Flare Expander Die ensures that your bullets seat properly and your final round is shaped properly.

To set up the Mighty Armory Flare Expander Die, turn the die into the station and insert a sized case on your shell holder. Raise the ram or lower the tool head all the way and adjust the flare die down until it just touches the case with minimal pressure.

Measure the outside diameter of the case’s mouth. Your case mouth outside diameter target is dependent on the size of the bullet you are using. Keep turning the die ¼ turn down and measure after each turn until you hit that target range. It might take a few extra minutes, but trust that the process will make all the difference when you’re loading.

Once you achieve the correct outside diameter of the case, measure the inside of the case with the back of the caliper – this is where the measured system is important. The goal is for the inside diameter (I.D.) to measure .003 to .004 less than the diameter of the bullet. For example, if you’re seating a .355 bullet, you want the I.D. to be between .352 to .351.

Brass thickness can vary and springback can cause variation in measurments. Set the bullet on top of the flared case, either by hand or with a bullet dropper. A correctly flared case will allow the bullet to sit straight on the case. This will minimize the risk of deforming the bullet during the seating process.

*If you’re not flaring the case enough, you will see the bullet through the case after seating and the case wall with not be straight after crimping. Turn your flare down another ¼ turn and flare again. It is important to understand that a variation in both the brass and bullet hardness can affect your measurements.

Step 3: Mighty Armory Bullet Seating Die Setup

The Mighty Armory 9mm Bullet Seating Die features a steel barrel system, which is angular at the front and shaped in a particular way at the top to accept a variety of different bullet shapes. The steel design was created to prevent bullet scarring, commonly seen when using a seating stem. The Mighty Armory Seating Die also closes the flare 80-90% while seating the bullet. As the die enters over the bullet, it only leaves about .005 of flare remaining. This means you’re holding a minimum of .004 of tension on the bullet pre-crimp.

Before turning the die into the press, turn the seating barrel up so that the barrel is inside the die. With the bullet on the flared case, raise the ram or lower the tool head. Turn the die down until you can feel pressure on the bullet and continue to turn it down. You are actually seating the bullet by hand.

Next take a measurement of the overall case length. For example, if you’re looking for a length of 1.075 inches, make adjustments accordingly. When target OAL is achieved, lock the die into place. The goal is to ensure that the bullet is seated correctly and securely, which is vital for accuracy.

Step 4: Mighty Armory Carbide Taper Crimp Die Setup

The Mighty Armory 9mm Carbide Taper Crimp Die is the finishing die and final step in the reloading process. This die is designed to crimp at a specific diameter based on the bullet you’re using. For example, for a .355 bullet, the measured system is designed to crimp at .355 to .377, depending on the bullet hardness. The softer the bullet the less crimp you want – so closer to .377 to .378 would be ideal.

Turn the die down onto the seated bullet. You should feel a snug resistance. Once the crimp die is set, measure the round to ensure it meets your specifications. Check for no bullet setback.

The crimping process ensures that your bullets will hold tight during cycling, which is essential for reliability and accuracy.

Reloading with Different Bullet Diameters

Now that we have the reloading dies set up, let’s explore how to reload and setting the diameters using different types of bullets. The versatility of the Mighty Armory dies allows you to work with various bullet styles, whether you prefer plated, coated, jacketed bullets, etc.

Use the following average measurements as a guide when reloading 9mm with Mighty Armory Full Length Reloading Dies.

Brass hardness and bullet hardness are very important in understanding spring back and measurements. For example, when crimping a very hard bullet like the Acura Outdoors .356, the crimp will likely remain less than .3785 but you will not get bullet setback.

Conclusion

When reloading 9mm with Mighty Armory’s carbide dies, you can feel confident that you’ll be reloading the best ammo possible. Mighty Armory unquestionably has the best Sizing Die Set in the Reloading Industry. Precision machined from the best materials will ensure your dies will remain consistent and in spec for a lifetime of cycling on your press.

Using the Mighty Armory measured system, you will achieve rounds that size full length in spec with SAAMI Standards. Reloading to SAAMI Spec results in increased brass life, proper angles for the round to feed out of the magazine, proper fit in the chamber, proper case pressures, cleaner powder burn and improved accuracy.

Reloading any caliber with a Mighty Armory Die Set is a rewarding experience that offers precision and consistency that you have never experienced. With the right setup and attention to detail, you can create precision reloads that will exceed your expectations. Whether you're a seasoned reloader or just getting started, these tips will help you achieve excellent results.

If you need assistance with setting up your reloading dies, call, text or email Wayne and he will gladly walk you through.

(401) 575-1288

Wayne@mightyarmory.com

For more information on Mighty Armory products, visit www.MightyArmory.com and explore the full range of reloading dies.