The Importance of Reloading to SAAMI Spec for Accuracy

KEY HIGHLIGHTS

- What Does SAAMI Spec Mean?

- Consistency Equals Accuracy

- Eliminating Variables for Enhanced Precision

- Optimized Ballistics for Predictable Trajectory

- Enhancing Accuracy Across Different Firearms

- How Deviations from SAAMI Spec Can Hurt Accuracy

- Mighty Armory Pistol Sizing Dies

- Mighty Armory Rifle Sizing Dies

Reloading offers a variety of benefits, from cost savings to the satisfaction of creating custom loads. However, the key to achieving consistent, safe, and accurate rounds is reloading to SAAMI (Sporting Arms and A Manufacturers’ Institute) specifications. SAAMI sets industry standards for firearm compatibility, covering dimensions, pressure limits, and cartridge performance. While the specs are critical for safety and reliability, they’re also a fundamental factor in optimizing accuracy. Mighty Armory specializes in the design and manufacturing of reloading dies that load to SAAMI Spec. Our pistol sizing die sets are famous for loading to SAAMI Spec.

In this blog, we’ll explore why sticking to SAAMI specs is essential to hitting the mark every time.

What Does SAAMI Spec Mean?

SAAMI is an organization that sets voluntary standards for the design and manufacture of firearms, and components. These specs cover every dimension and detail of a cartridge:

- Chamber and cartridge dimensions

- Pressure limits

- Bullet diameter and shape

- Case length

Adhering to these specifications means your reloads will fit securely and perform reliably in any firearm chambered for that specific cartridge. But SAAMI specs do more than ensure safe firing—they’re also designed to promote uniformity across each round, which is crucial for achieving consistent accuracy.

Consistency Equals Accuracy

Accuracy is all about consistency, and SAAMI specs are tailored to help reloaders achieve exactly that. When you load your rounds to precise, repeatable dimensions, you create cartridges that will perform predictably shot after shot. Here’s how sticking to SAAMI specs can improve accuracy:

- Uniform Pressure Generation: Pressure consistency is key for precision shooting. Over-pressure or under-pressure can throw off a bullet’s velocity, affecting its trajectory. SAAMI specifications help ensure each round generates the same pressure, so your shots are consistent.

- Repeatable Seating Depth: Bullet seating depth influences the amount of “jump” a bullet has before it engages with the rifling. SAAMI specs provide an ideal range for seating depth, allowing reloaders to find a sweet spot for each round. By keeping bullets seated at a uniform depth, reloaders can minimize variations in point of impact, resulting in tighter groupings.

- Precise Cartridge Length: Cartridge Overall Length (COL) is another crucial factor for accuracy. A consistent length helps each round chamber identically, leading to the same alignment of the bullet with the bore. Variances in length can affect how the bullet engages with the rifling, impacting both velocity and trajectory.

Eliminating Variables for Enhanced Precision

When it comes to shooting accurately, even the smallest inconsistencies can translate into noticeable differences downrange. Reloading to SAAMI spec helps to eliminate many of these variables:

- Case Length Control: Over time, brass cases can stretch or become misshapen through repeated use. Reloading to SAAMI standards includes trimming and resizing cases to meet specified lengths, which helps to ensure a snug fit in the chamber. Uniform case length allows the primer, powder, and bullet to interact consistently, which is essential for maintaining shot-to-shot precision.

- Consistent Powder Loads: SAAMI specs also influence powder recommendations. Following these guidelines ensures you’re using an amount that keeps pressure within safe limits and reduces velocity variations. A well-measured, consistent powder charge produces reliable muzzle velocities, minimizing changes in trajectory across rounds.

- Neck Tension: Bullet tension in the case neck can also influence accuracy. If neck tension varies, it affects how the bullet exits the cartridge and engages with the rifling. SAAMI specs help reloaders achieve uniform neck tension, which directly affects how smoothly bullets transition from the case to the barrel, improving accuracy.

Optimized Ballistics for Predictable Trajectory

Accuracy doesn’t stop with bullet impact; it extends to how the bullet reaches the target. SAAMI specs are designed to optimize the ballistic path by ensuring consistent bullet performance from launch to impact:

- Consistent Muzzle Velocity: With SAAMI specs, each round produces similar velocities, which means the bullet follows a repeatable trajectory. Variances in velocity lead to changes in bullet drop and wind drift, both of which can hinder accuracy at long ranges. Loading to SAAMI spec helps achieve the tightest standard deviation in velocity, producing a predictable point of impact.

- Uniform Bullet Shape and Weight: While bullet shape and weight vary among manufacturers, SAAMI provides a standardized range that promotes compatibility. This ensures reloaders can choose bullets with similar profiles that perform consistently, reducing potential ballistic variations.

Enhancing Accuracy Across Different Firearms

One of the greatest benefits of reloading to SAAMI specifications is the compatibility it ensures across firearms. If you own multiple guns chambered in the same caliber, SAAMI-compliant rounds will perform predictably in each one.

- Consistent POI (Point of Impact): Different firearms, even those chambered for the same caliber, can have slight variations in barrel dimensions and rifling. By loading to SAAMI standards, you ensure a base level of compatibility that minimizes the impact of these differences on accuracy, maintaining a consistent POI.

- Reduced Wear on Components: Oversized or undersized cartridges can cause extra wear on firearms, which in turn can affect accuracy over time. Loading to SAAMI specs reduces wear, keeping your firearm’s components in top shape and preserving its accuracy.

How Deviations from SAAMI Spec Can Hurt Accuracy

Reloaders may be tempted to push beyond SAAMI specs in search of a “perfect” custom load, but deviating from these guidelines can compromise accuracy:

- Pressure Fluctuations: Minor changes in powder load, seating depth, or case length can lead to significant pressure variations. Pressure is the driving force behind the bullet’s velocity, and inconsistencies can cause erratic bullet flight.

- Bullet Jump Variability: Adjusting seating depth outside of SAAMI specs can lead to unpredictable engagement with the rifling, affecting accuracy. While some shooters find accuracy improvements by experimenting with seating depth, staying within SAAMI limits ensures the bullet jump remains in an optimal range.

- Always consult with your powder company’s manual for powder charge, bullet weight and COL.

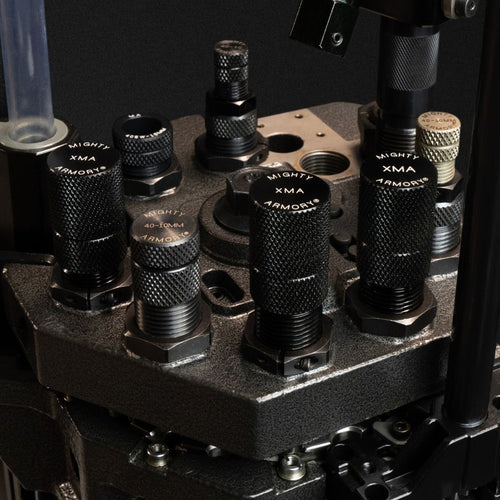

Mighty Armory Pistol Reloading Dies

Mighty Armory Pistol Reloading Dies were the first ever SAAMI Spec dies launched to the consumer in 2019. The sizing die diameters were engineered based on modern day pistol case sizes, which are a slight variance from the original SAAMI Spec case diameters, verified with SAAMI.

The measured system diameters for all of our pistol sizing die sets are noted in the descriptions of each die.

Flare measurements depend on bullet diameter:

- 9mm & 38 Super: Flare to .377 to .384

- .38 Special & .357 Magnum: Flare to + .002 to .003

- .40 S&W & 10mm: Flare to .423 to .425

- .45 ACP: Flare to .474 to.475

Crimp Measurements will vary depending on bullet and case thickness:

- 9mm: Crimp to .375 to .378

- .38 Special & .357 Magnum: Crimp to .378 to .381

- .40 S&W & 10mm: Crimp to .418 to .420

- .45 ACP: Crimp to .468 to .470

Check out the Mighty Armory YouTube channel for the details on our measured system for reloading 9mm.

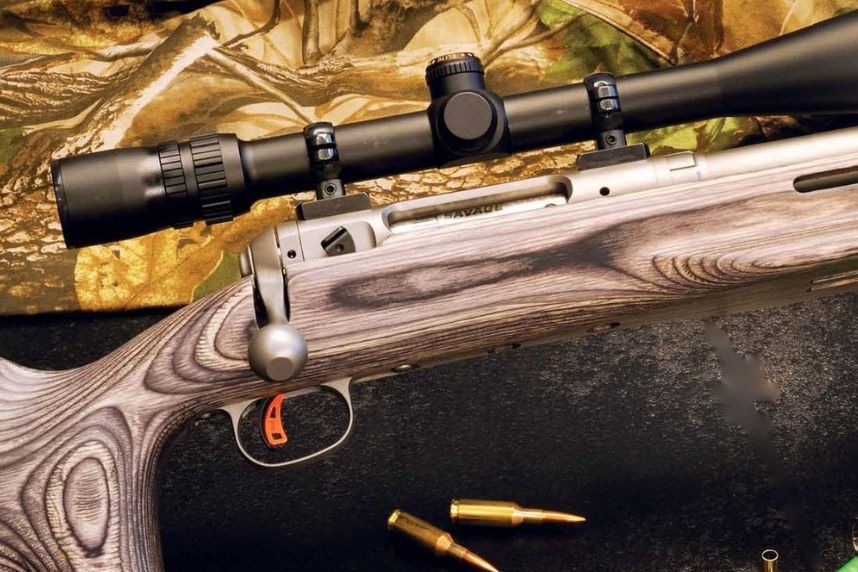

Mighty Armory Rifle Reloading Dies

Mighty Armory Gold Match Rifle Sizing Dies are precision machined one at a time, heat-treated, with a polished bore to a smooth eight to ten finish, ensuring smooth and pressure-free sizing. With an average runout ranging from .0005 to .0001, you can count on unmatched consistency. Bullet tension is finely tuned, varying from .002 to .004 depending on caliber, providing optimal performance. Achieving the perfect headspace bump is simple—adjust the die up or down, typically between .002 and .005, for more add camover. The shoulder and neck radius diameters are fully within SAAMI specifications, making these dies a reliable choice for both hobbyists and long-range competitors alike. Proven by countless competition wins nationwide, our dies deliver the precision you need for success at any level.

Final Thoughts: SAAMI Specs as the Foundation for Accuracy

Reloading to SAAMI specifications isn’t just about safety—it’s the foundation of producing accurate, repeatable reloads. By adhering to these standards, you reduce variables that affect each round’s performance, ensuring every cartridge delivers predictable results. Reloaders who prioritize SAAMI specs can expect their loads to perform reliably and accurately, giving them confidence that each shot will go where it’s intended. So, next time you sit down to reload, keep in mind that precision begins with respecting the specifications that ensure accuracy.